What is the function of the filter of the orifice sintered mesh?

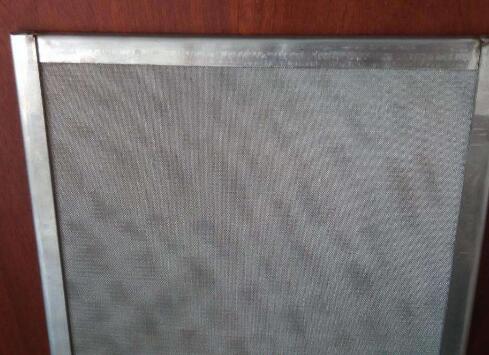

Porous plate sintered mesh filter has a wide range of reference value in the national industry, environmental protection and many industries. The orifice sintered mesh has an excellent stainless steel filter, so what are the functions and advantages of the orifice sintered mesh filter? Let's take a look together.

First of all, the main function of the orifice sintered mesh filter is gas filtration. We must know that industrial gases and many gases in the environment contain many bacteria, dust and other impurities. If it is discharged directly into the air, it will have a great impact on our body. The damage is huge, so we have to use a perforated sintered mesh filter to filter the gas, bring it up to emission standards, and then let it out.

The advantage of this machine is that it can be used in many industries and many products. Orifice sintered mesh can be used in oil filters, air purifiers, dust collectors and many other products, so although it is only a small accessory in China, the market reference prospect is very broad. It eliminates many types of impurities, including gas, dust, bacteria and particles, which can be removed by installing a perforated sintered mesh filter on the device, which cannot be achieved by many other filtering devices. Although there are many other brands competing with *** in this product field, *** has mastered the core technology of this accessory manufacturing, and I believe there will be good development in the future.

In the orifice sintered mesh filter, the processing quality will directly determine its own service life. In order to prolong its service life, daily maintenance is also essential.

When the filtration accuracy meets the requirements, the orifice sintered mesh filter element processing should have high passability, and the orifice sintered mesh filter element has a strong oil passage capacity to ensure smooth circulation of the system, and the pressure it accepts will be reduced. If the pressure difference is too large, it will not only damage the structure of the filter, but also affect the working efficiency of the transmission.

At the same time, the strength of the orifice sintered mesh filter element should also meet the standard. The strength is related to the pressure bearing capacity of the orifice sintered mesh filter. The pressure in a hydraulic system is not constant. According to the working intensity and time, the switching power supply is switched, the pressure changes, and the orifice plate sintered mesh is good. The mesh filter not only has to withstand high pressure, but also has fatigue resistance to maintain its structural strength and not easy to lose under the changing pressure.

In addition, the selection of the orifice sintered mesh filter element is also very important, and the filter material of the orifice sintered mesh filter element must have sufficient corrosion performance. At the same time, if the orifice sintered mesh filter element is made of metal material, it is easy to rust, so it is necessary to use additives.