What is the sintered mesh made of?

Sintered mesh is a new type of filter material with multi-layer sintered mesh, which is made of multi-layer metal braided wire mesh through special lamination and vacuum sintering process. It has high mechanical strength and overall rigid structure. Each layer of wire mesh is staggered with each other to form a uniform and ideal filter structure, which not only overcomes the shortcomings of ordinary wire mesh such as low strength, poor rigidity, and unstable mesh shape, but also reduces the permeability and strength characteristics of the pore size material to obtain a reasonable Matched and designed so that it has excellent filtration precision, filtration resistance, mechanical strength and processability, and its overall performance is significantly better than that of sintered metal powder, ceramics, fiber, filter cloth, filter paper and other types of filter materials.

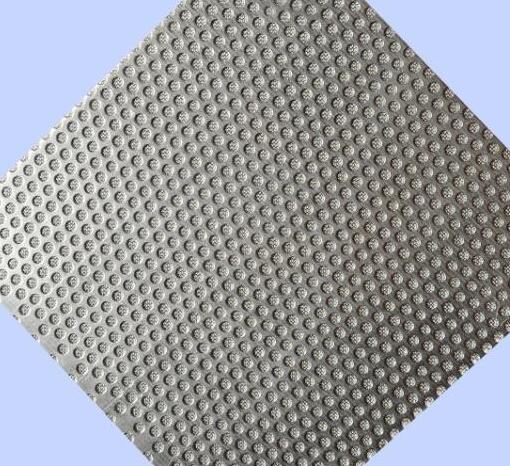

Sintered mesh structure:

It is usually divided into five layers and divided into four parts: protective layer, filter layer, separation layer and support layer. This filter material not only has uniform and stable filtration accuracy, but also has high strength and rigidity. It is an ideal filter material for the occasion of uniform filter particle size. Since its filtration mechanism is surface filtration and the mesh is smooth, it has excellent backwash regeneration performance and can be used repeatedly for a long time. It is especially suitable for continuous and automated operating processes. It is unmatched by any filter material. The sintered mesh material is easy to form, process and weld, and is easy to manufacture, and can be processed into various forms of filter elements, such as round, cylindrical, conical, corrugated, etc.

Sintered mesh characteristics:

1. High strength and good rigidity: It has high mechanical strength, good processing, welding and assembly performance, and is easy to use.

2. Uniform and stable precision: Uniform filtration performance can be achieved on all filtration precisions, and the mesh will not change during use.

3. A wide range of use environments: it can be used in a temperature environment of -200°C to 600°C, and can be filtered in an acid-base environment.

4. Excellent cleaning performance: good countercurrent cleaning effect, reusable and long service life (can be cleaned by countercurrent water, filtrate, ultrasonic, melting, baking, etc.).