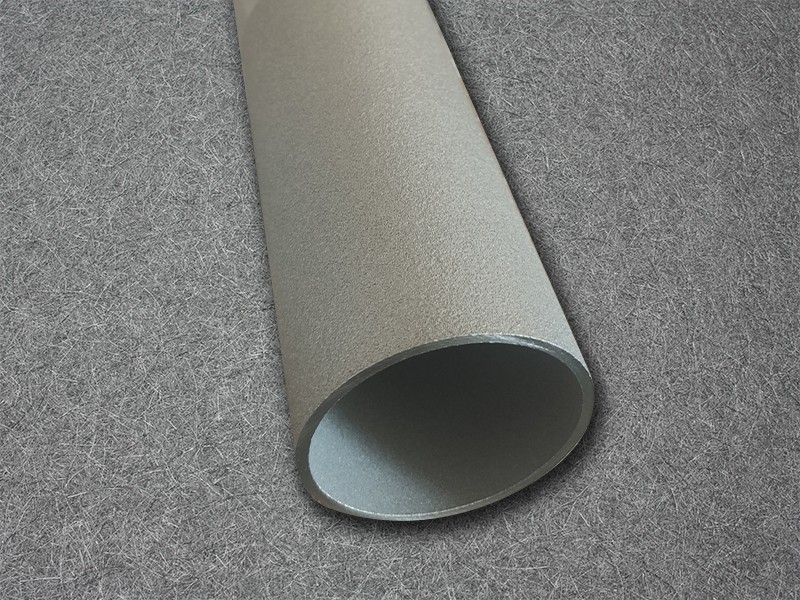

Stainless steel powder filter element is made of high-quality stainless steel powder by high-pressure molding and high-temperature sintering. Through the screening and grading of high-quality raw materials, products with different filtering accuracy of 0.1-100 microns can be achieved. With strict molding, pressing and sintering welding process, stainless steel filter elements with high porosity and uniform pore diameter can be obtained. At the same time, they have high strength, good toughness, corrosion resistance, high temperature resistance and other properties.

The raw materials of stainless steel powder filter elements are widely selected, such as 316L, 304L, 310S, 321, 904L, etc. At the same time, nickel based alloys such as Hastelloy, Monel, Inconel, etc. can be used as raw materials to prepare filter elements. Therefore, customers can choose filter elements of different materials according to the actual working conditions.

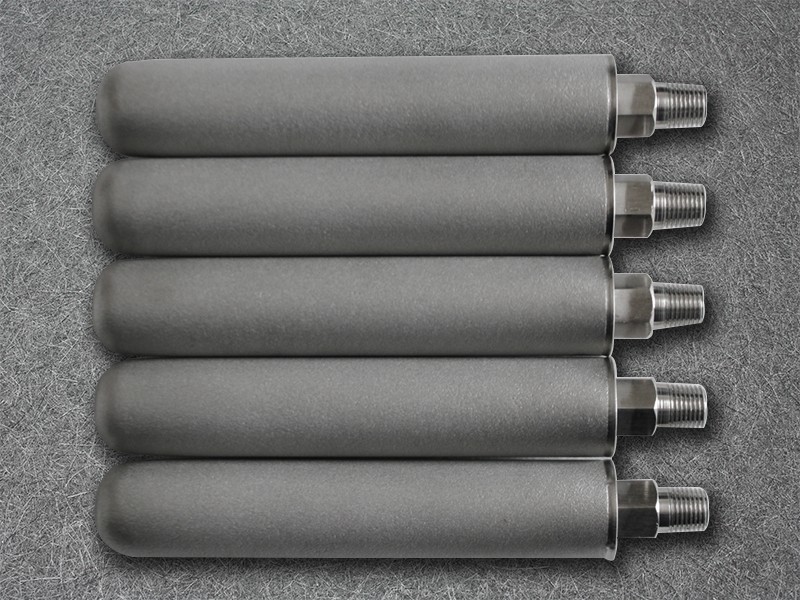

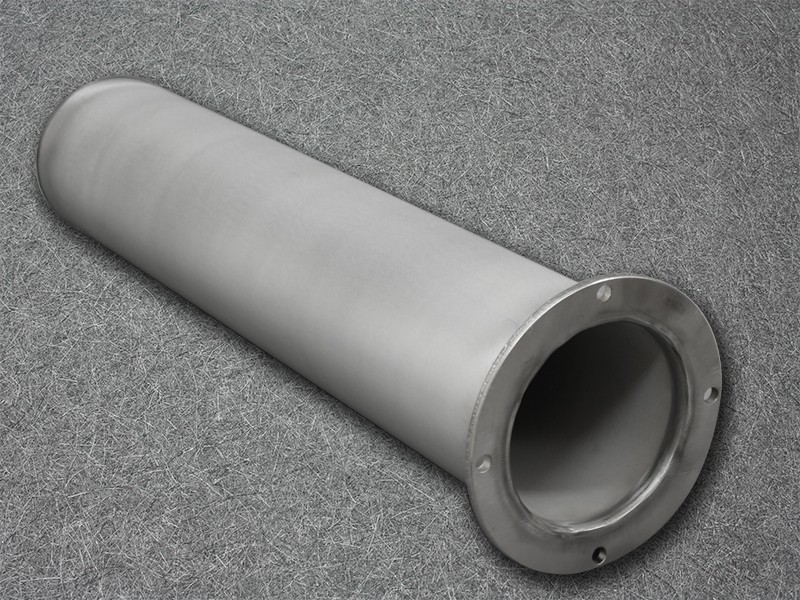

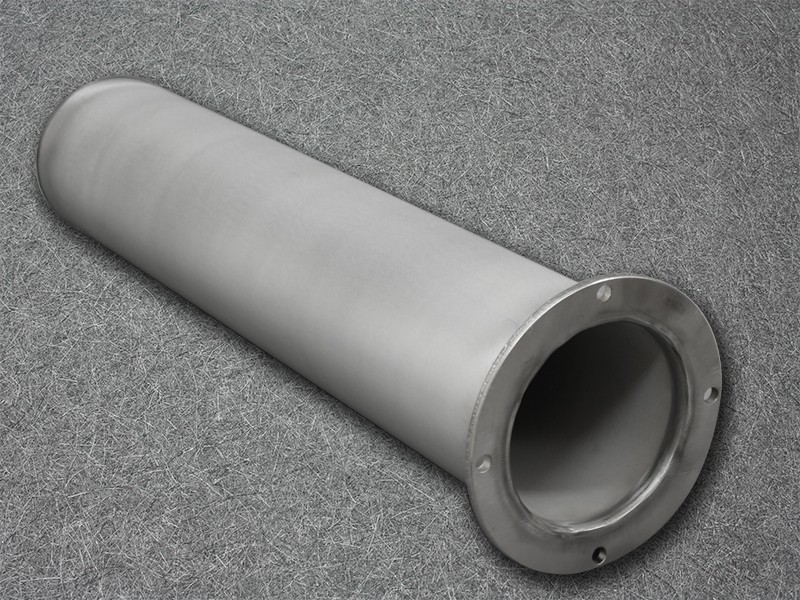

There are four types of powder filter elements: single-layer filter element (JW-DC), double-layer filter element (JW-SC), coated filter element (JW-TC), and axial pressure filter element (JW-ZY).

Single layer products (JT-DC) are our conventional products, which can be made into tubular, cylindrical, conical and other shapes. The products are widely used in chemical, pharmaceutical, environmental protection, metallurgy, food and beverage, petrochemical and other fields.

The double-layer product (JW-SC) has a double-layer structure. By matching powders with different particle sizes and adopting a one-time molding process, the gradient distribution of pore diameter can be achieved. The double-layer structure plays the role of support and filtration at the same time, and the gradient pore structure has better permeability than conventional products, reducing the differential pressure. Double layer product is a new solution for cross flow filtration in chemical, pharmaceutical and other fields.

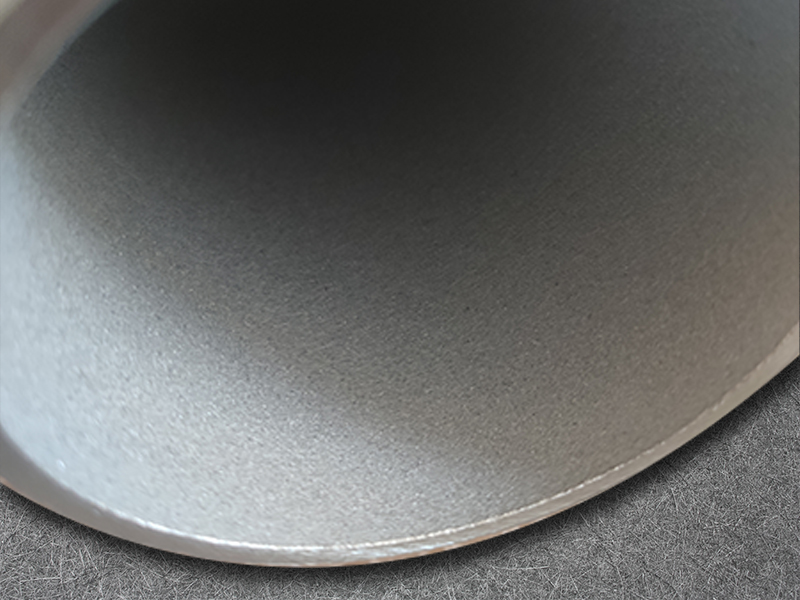

The coating product (JW-TC) is a high-precision membrane filtration product, which achieves excellent filtration effect and high permeability. The utility model comprises a filter layer and a support layer, which can obtain products with high adhesion and good mechanical strength after high-temperature sintering. TC products have ultra-fine spherical powder filter layer, and the filtering accuracy can reach 0.1 μ m.

Gold titanium axial compression products (JW - ZY) are usually various small size discs and tubes. The precision casting mold and precise pressure control can control the dimensional tolerance of products in a smaller range to meet the needs of various customers.

technical parameter

Large differential pressure: 80 ℃, 3.5Kg/; 235℃,3.2Kg/

Precision: liquid 0.5um - 5um; Gas 0.01um - 20um

Materials: stainless steel, bronze, nickel, monel alloy, Hastelloy.

The metal melting sealing process is adopted, and the operating temperature range can reach - 200 ℃~500 ℃.

Product characteristics

High pressure resistance, good impact resistance and alternating load capacity.

Air permeability, stable separation effect.

Fixed hole structure.

High mechanical strength and wear resistance.

High and low temperature adaptability and chemical stability.

Online repeated cleaning and back blowing can be carried out.

Specification and model

Diameter: ¢ 20, ¢ 30, ¢ 35, ¢ 50, ¢ 60, ¢ 70, ¢ 80, ¢ 135, and non-standard customized

Length: 5 inches (125mm), 10 inches (250mm), 12 inches (300mm)

20 inches (500mm), 30 inches (750mm), 40 inches (1000mm)

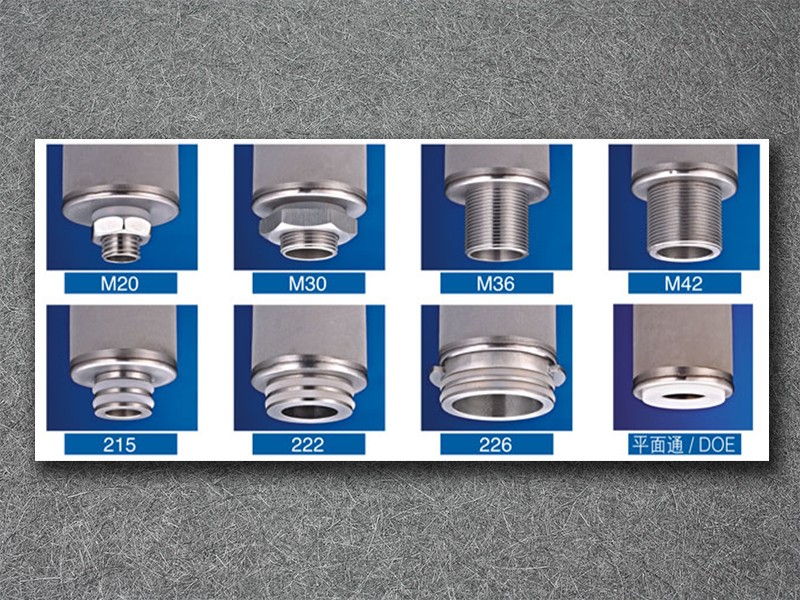

Interface type: M20 interface, M30 interface, 222 interface, 226 interface, double flat port, flange

Filtering precision: 0.01um, 0.1um, 0.2um, 0.5um, 1um, 2um, 5um, 10um, 20um, 40um

Product Specification Sheet

Test standard: bubble point test ISO4003 GB/T5249 Air permeability test GB/T31909

The regular product Jiuwei adopts the random sampling inspection method, which is 10% of the total contract quantity, and the special product is 100% of the total contract quantity.

Typical Applications

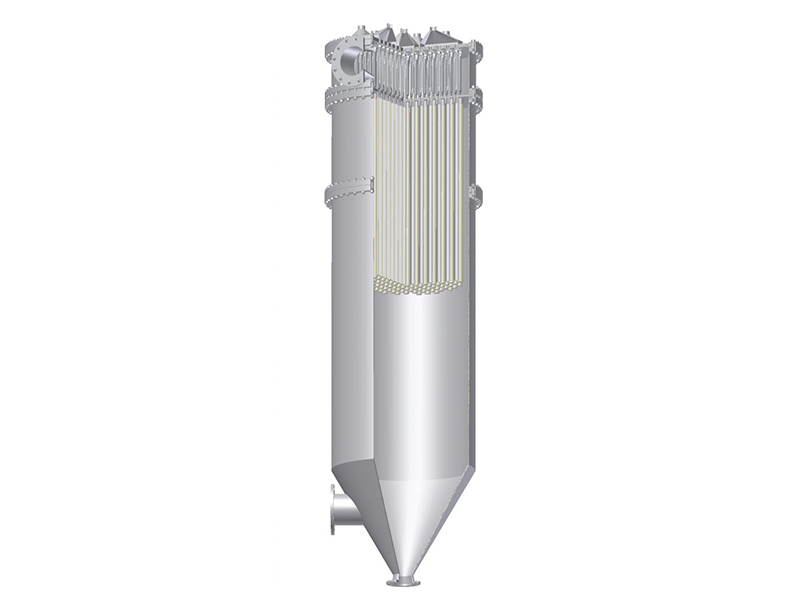

■ Filtration and recovery of catalyst;

■ Filtration of petrochemical high-temperature gas;

■ Purification of high-temperature flue gas in metallurgical industry;

■ Recovery of dust in the tail gas of solid fluidized bed;

■ Dust and tail gas purification in thermal power generation and nuclear power generation industries;

■ Filtration of liquid products and liquid raw materials in the chemical industry.