Previous:Metal powder filter tube

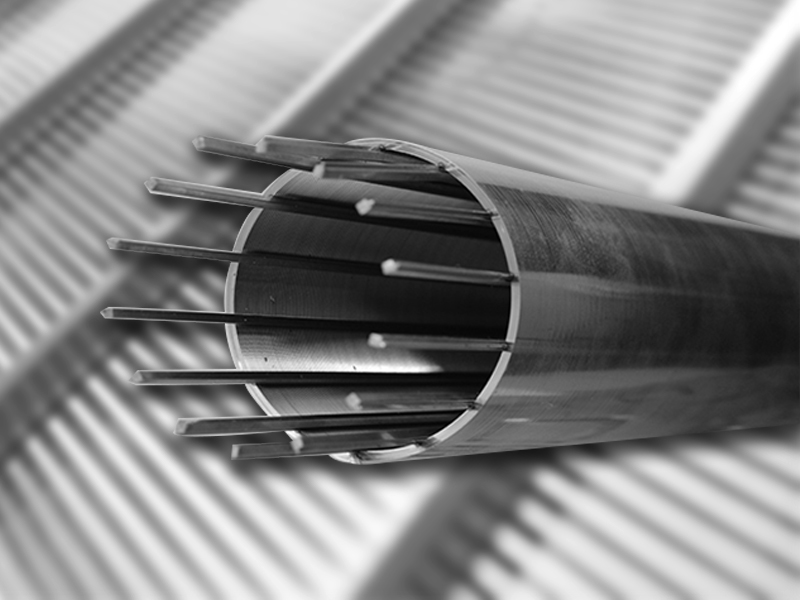

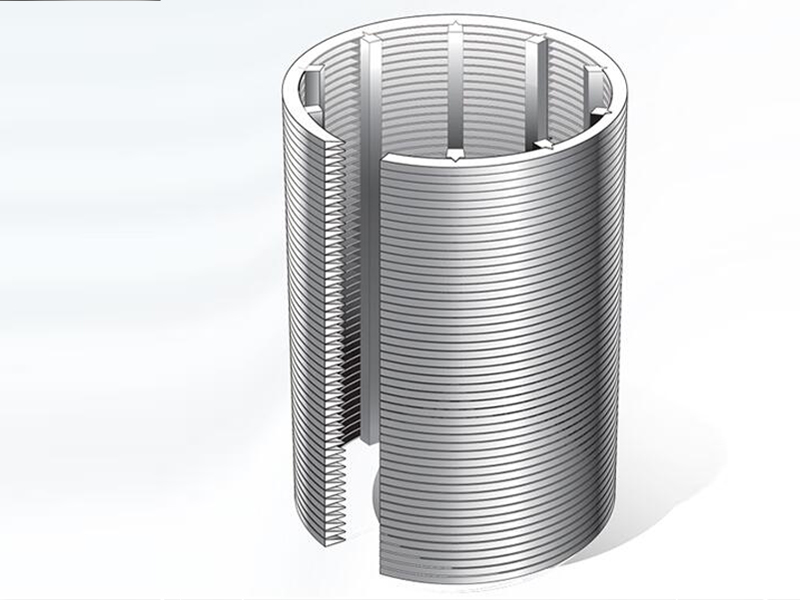

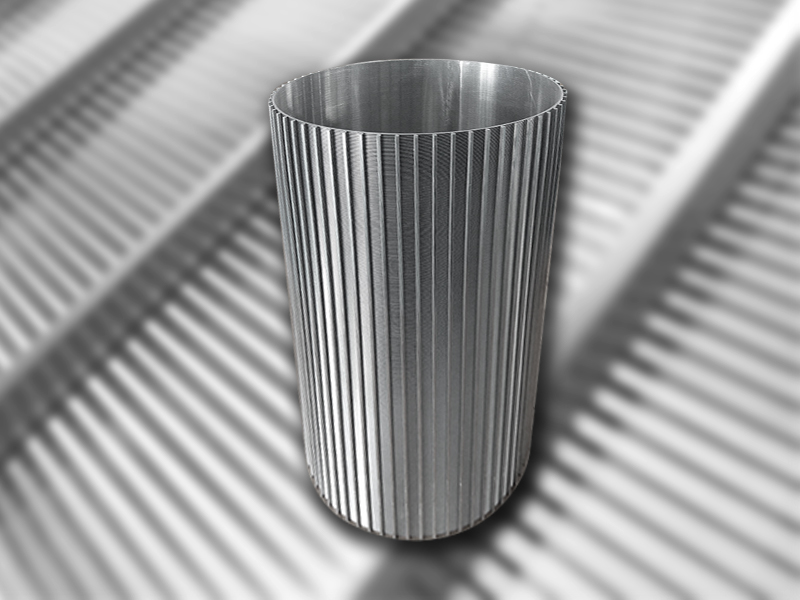

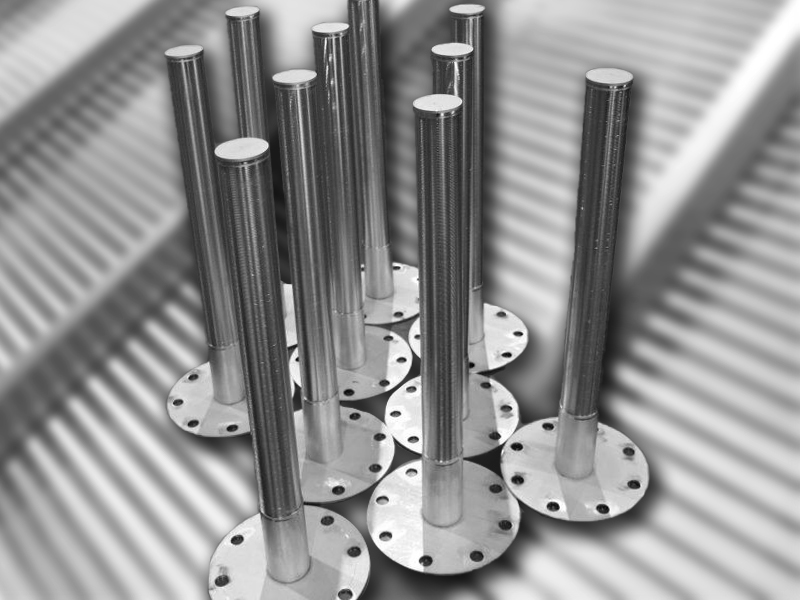

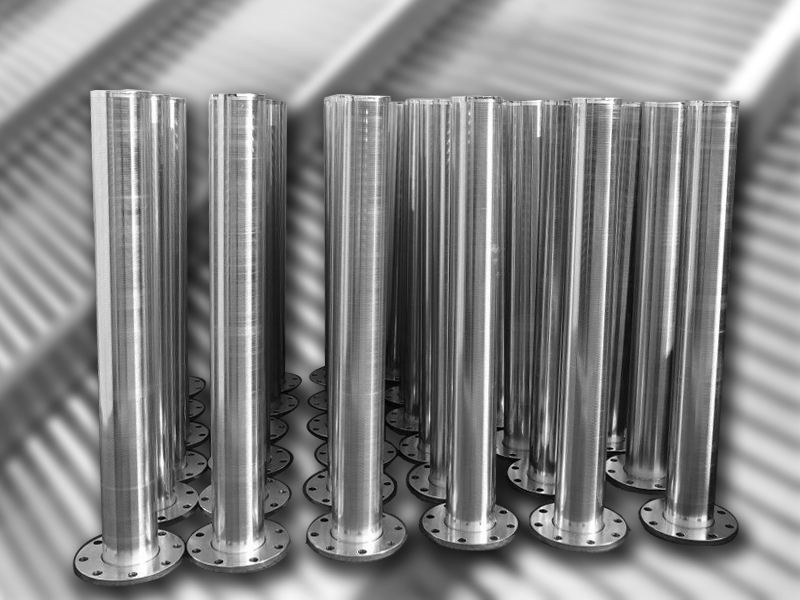

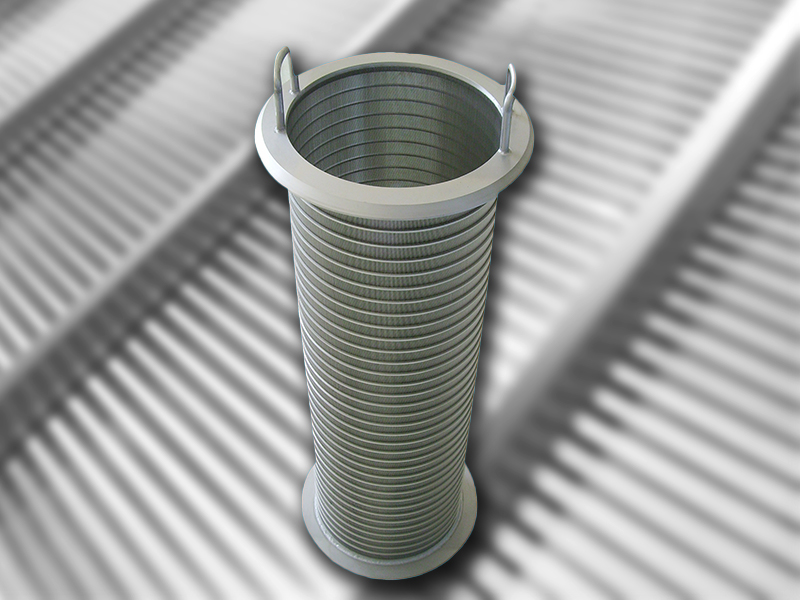

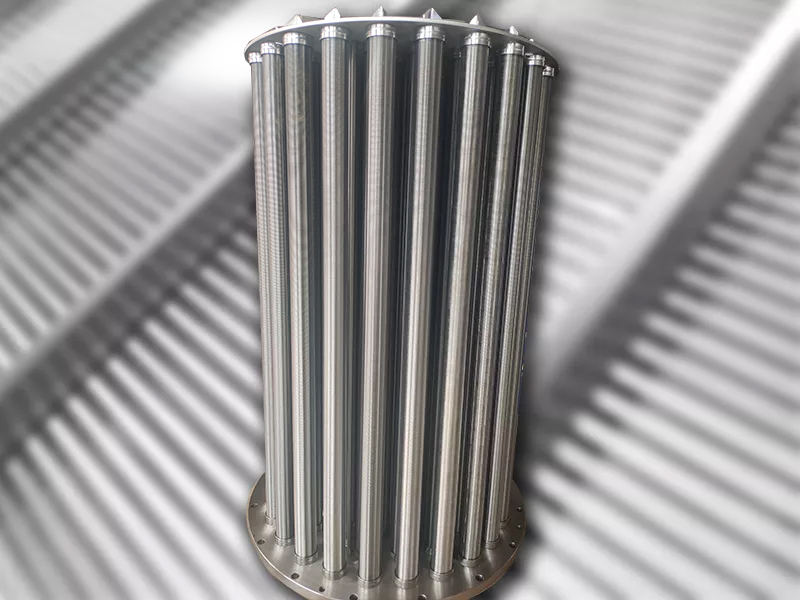

Wedge wire winding pipe is divided into two types: wedge wire winding screen pipe and wedge wire winding screen plate.

Stainless steel wire screen pipe, wedge type all welded trapezoidal wire wound screen pipe, stainless steel wire wound filter pipe, trapezoidal galvanized wire screen pipe, drilling triangle filter pipe, Johnson trapezoidal screen pipe, drilling wedge wire screen pipe, oil sand screen pipe, sewage screening filter pipe. When drilling, seam the screen pipe around the trapezoidal wire, and when drilling, weld the sand pump filter pipe.

Filter element material

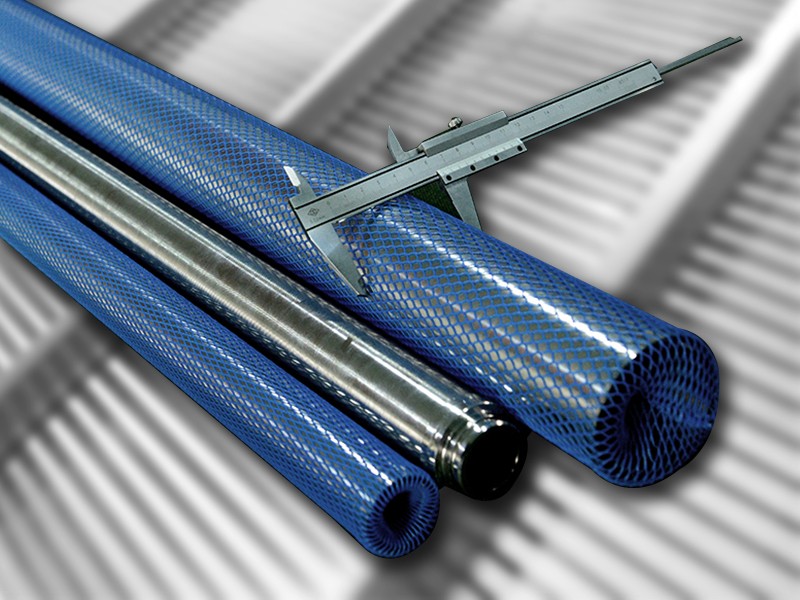

Material: 302, 304, 304L, 316, 316L stainless steel wire, low carbon steel wire, galvanized wire, etc. can also be made according to customer requirements.

Structural principle

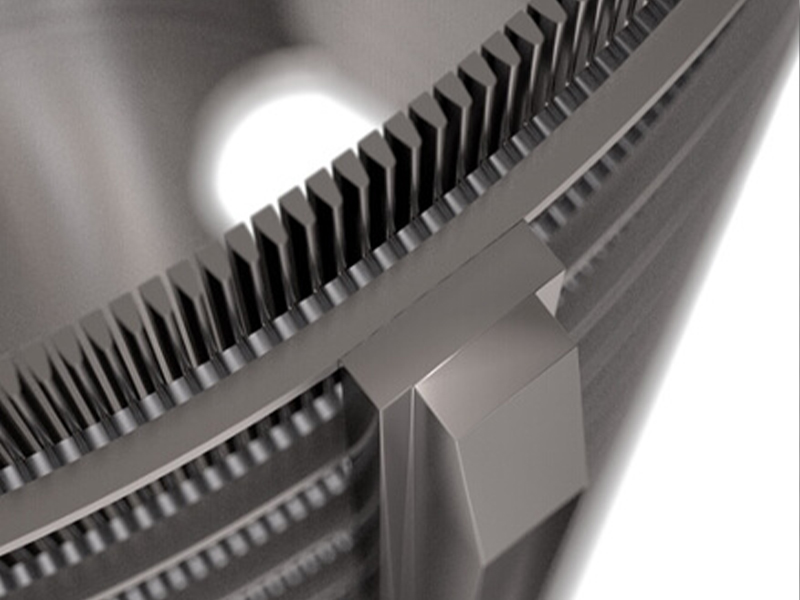

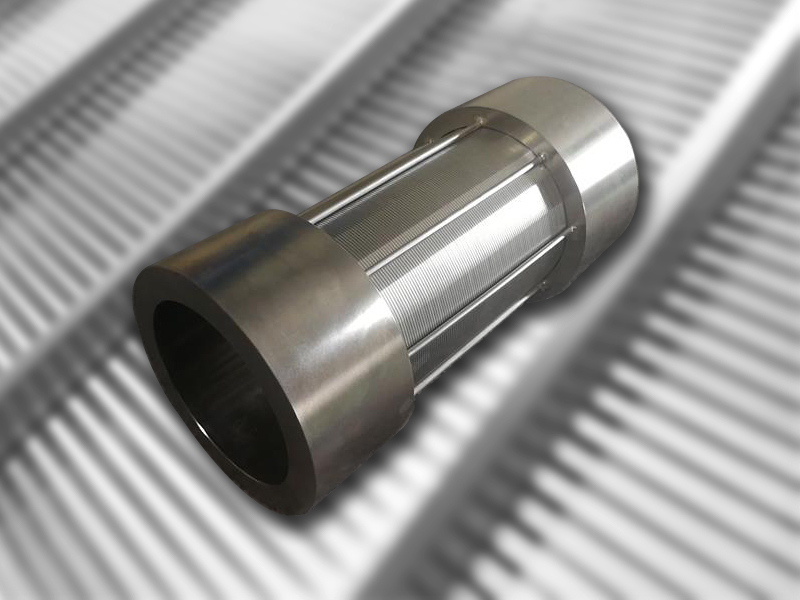

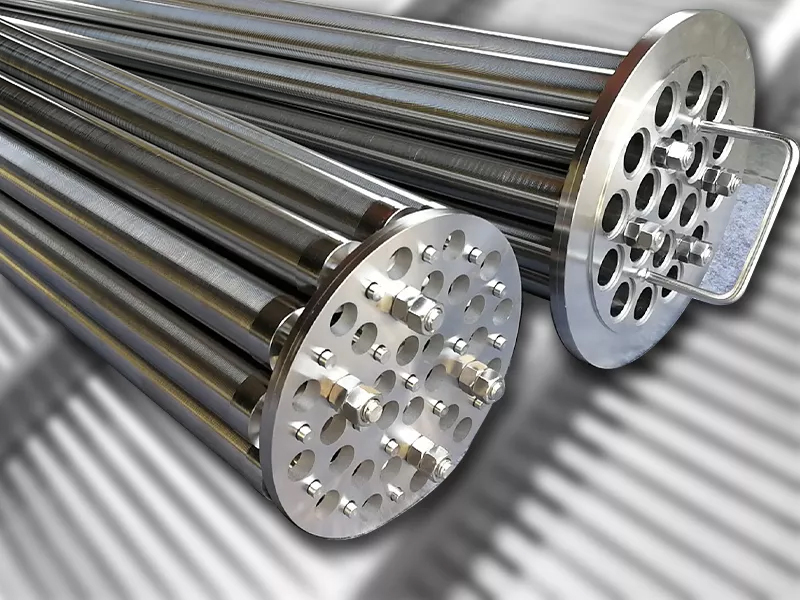

The screen pipe is composed of the surface wire helically wound on the axial support rod, and the support rod and the surface wire are connected to each other by resistance welding. The support wire can be triangular wire or trapezoidal wire, which is triangular wire (V-shaped wire), with accurate pore size and high filtering accuracy; It is characterized by firm structure, high temperature resistance, corrosion resistance, good mechanical performance, long service life, safety and reliability.

Silk specification

Wire width (mm): 1.50 1.80 2.30 3.00 3.30 3.70

Line height (mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30

Article specifications:

Wire width (mm): 2.30 3.00 3.30 3.70

Line height (mm): 2.70 3.60 4.70 5.60 6.30

Round line: between 2.50 mm and 6.0 mm

It can also be produced according to customer requirements.

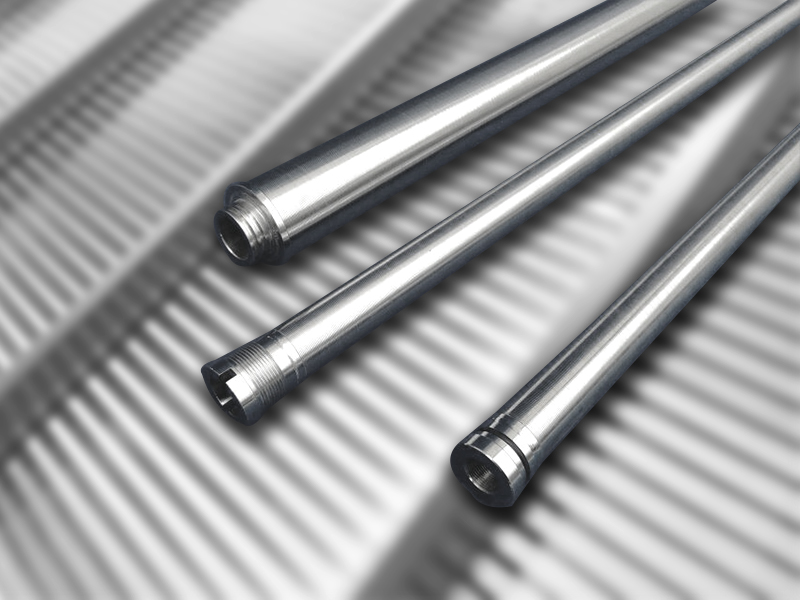

Connection mode: welding and threaded connection.

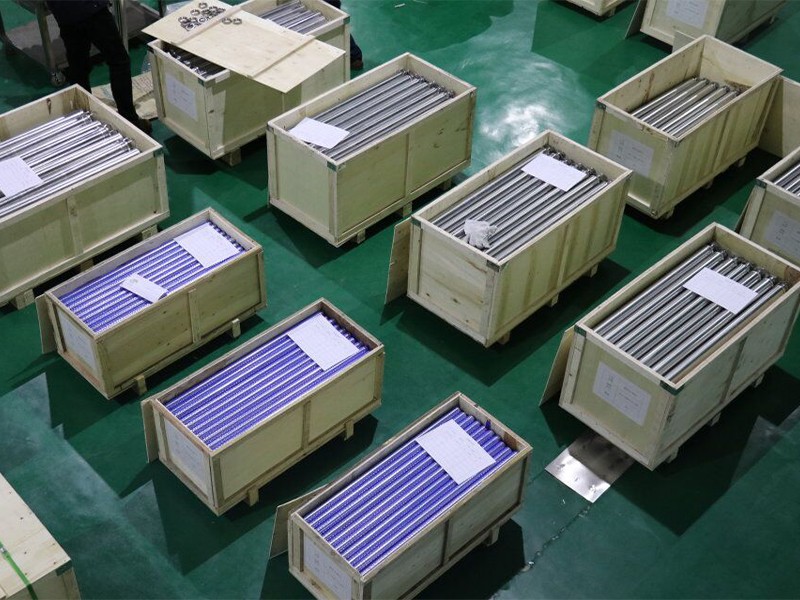

Standard length: 3m/5.85m.

Remarks: The small precision of wedge filter screen can reach 15 microns, about 650 meshes. Small diameter can reach 20mm, large diameter can reach 1000mm, and length can reach 3000mm. It can be customized according to customer requirements.

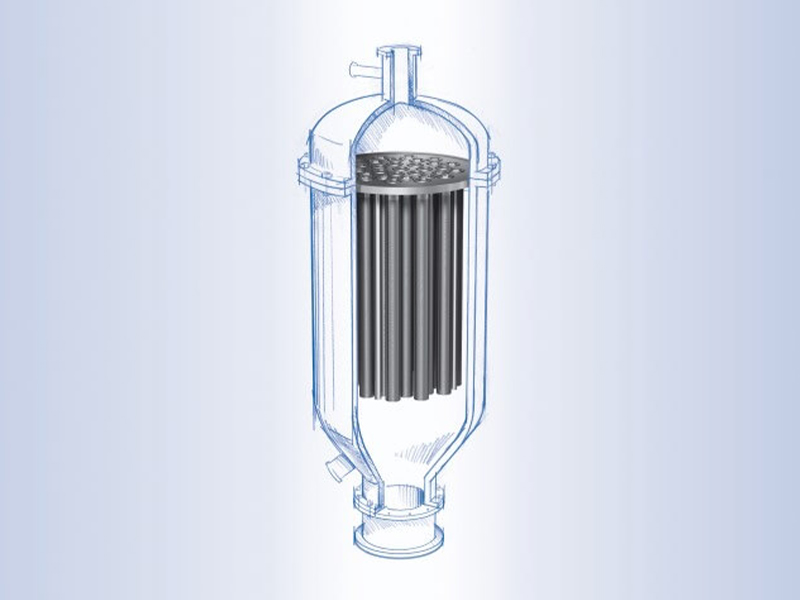

working principle

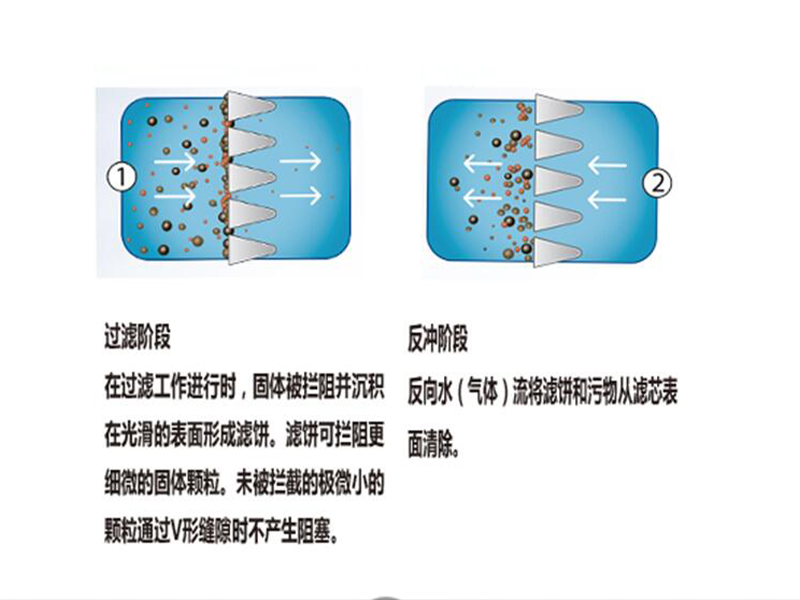

The V-shaped design adopted by the filter unit enables the fluid to pass through the surface of the wedge-shaped filter element under the pressure. The pressure gradually increases and the filtering accuracy slowly improves. The final solid particles will be intercepted on the surface of the filter element, and the clear liquid will be discharged from the shell to enter the next process.

How to select filter element requires comprehensive consideration of various factors. Different water flow directions and different backwashing methods will change the weaving method of the wedge-shaped mesh. Diversified design and different wedge-shaped filter elements will be used for efficient filtration to meet the filtering requirements.

Performance characteristics

◆ The winding process can reduce the pressure loss to a low level according to the trend of the fluid

◆ Make reasonable preparation according to the flow direction

◆ High strength process can greatly improve the compression resistance

◆ The filtration requirements of high viscosity and large flow are reasonably solved

◆ The service life can be as long as ten years, which is suitable for frequent cleaning and saves the production cost of the enterprise

◆ Its filtering precision can reach 20um, and different precision can be customized according to needs

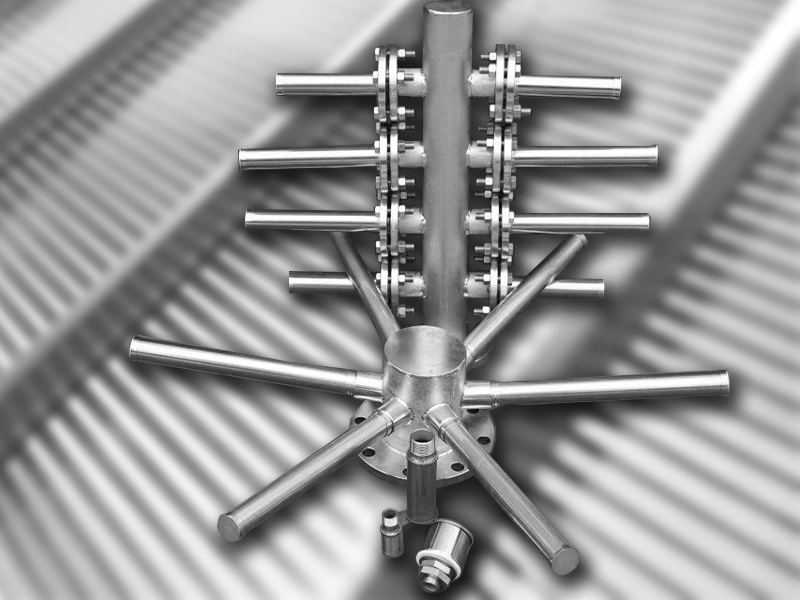

◆ Reinforcing method: punching pipe, cross, flange ring.

purpose

The filtering water pipe is a kind of pore water filtering equipment. It can be used together with deep well pumps and submersibles, as well as for water treatment equipment, environmental protection, dilution treatment of aqueous industrial water and domestic water, tap water treatment, softened water, petrochemical industry: oil terminal filtration, chemical acid and alkali liquid filtration, and alcohol solution recovery filtration.