Previous:PP meltblown filter element

Name: PP microporous pleated filter element

Filter Length: 10", 20", 30", 40", 50", 60"

Applicable PH: 1~13

Maximum differential pressure: 4.0Bar

Operating temperature: 1Bar 80°C, > 50°C stainless steel support ring is recommended

Sterilization: Resistant to 121°C, in-line steam sterilization for 30 minutes

Addable end cap material: Polypropylene

Interface type: flat press-in type (other interfaces can be added)

Filter precision: 0.1, 0.22, 0.45, 1, 3, 5, 10, 20, 50(μm)

Gasket/sealing ring: silicone rubber, ethylene propylene rubber, nitrile rubber, fluorine rubber

customized according to different working conditions

Ask For Quote

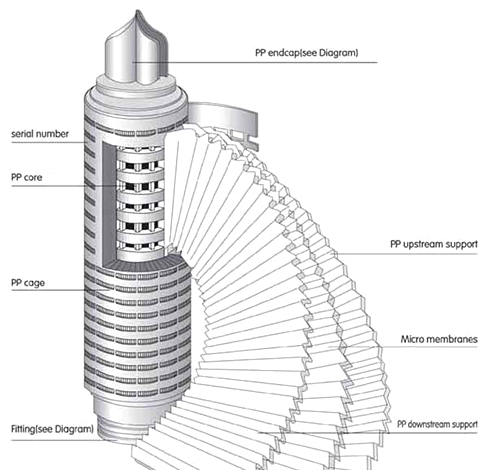

PP microporous folded filter element

The main characteristics of microporous membrane folding filter element: high rejection, high flow flux, low pressure difference and wide chemical compatibility; The production process adopts unique hot-melt welding processing technology, without any adhesive or foreign matter release. Meet the production requirements of food, beverage, beer, chemical industry, pharmaceutical and other industries.

Application

pharmaceutical industry, food industry, electronic industry, petroleum and chemical industry, etc.

Filter media

suspended solids, particles, water quality dirt, bacteria and algae, rust, etc

Name: PP microporous pleated filter element

Filter Length: 10", 20", 30", 40", 50", 60"

Applicable PH: 1~13

Maximum differential pressure: 4.0Bar

Operating temperature: 1Bar 80°C, > 50°C stainless steel support ring is recommended

Sterilization: Resistant to 121°C, in-line steam sterilization for 30 minutes

Addable end cap material: Polypropylene

Interface type: flat press-in type (other interfaces can be added)

Filter precision: 0.1, 0.22, 0.45, 1, 3, 5, 10, 20, 50(μm)

Gasket/sealing ring: silicone rubber, ethylene propylene rubber, nitrile rubber, fluorine rubber

customized according to different working conditions

Adopt internal thread structure to enhance compression resistance:

Wide chemical compatibility, large flow capacity, low pressure difference, It can be cleaned and regenerated, which is economical, Use chemical method and online steam sterilization.

Food grade materials:

Filter medium: polypropylene fiber membrane Upstream and downstream support material: Polypropylene Support frame and structural element: Polypropylene Sealing materials: silicone rubber, nitrile rubber, EPDM, fluororubber.

Support Customization:

Various interface displays can be customized by calling.

Working Principle

High dirt retention capacity, deep to achieve the effect of truly capturing particles by density classification, so as to give full play to the effectiveness of the filter element; Higher dirt retention capacity means longer service life and lower replacement frequency, resulting in cost savings; The surface of the filter element is toward the center, and the density increases gradually.

Different interface selection of folding filter element